Fiber Distribution Box

Fiber Distribution Box (FDB) is also called optical distribution box (ODB), which is used for outdoor, building or indoor connection of backbone fiber optic cable and fiber optic distribution cable interface equipment. Through the adapters, bring the optical signals with fiber optic patch cord or drop cable with fast connectors or optical splitters. Therefore, fiber distribution box also called fiber optic splitter box, network access point (NAP) box or fiber access network (FAT) box, in Spanish called caja de terminal optical (CTO) box. It is widely used for protection connection of cable and pigtails, also for the fiber optic termination point in fiber optic access network.

The fiber optical distribution box must be able to work reliably in the specified environment, and its box can withstand a vertical pressure.

Environmental Requirements

Type | Operating temperature | Relative Humidity | Atmospheric pressure |

Indoor | -10℃~+40℃ | ≤85%(+30℃) | 70kPa~106kPa |

Outdoor | -40℃~+60℃ | ≤95%(+40℃) |

The classification and naming of Yingda’s boxes is roughly as follows: outer appearance, number of entrance and exit cable ports, and internal configuration.

CTO Series (Caja de Terminal Optical Box)

The distinctive feature of this series is that the cable outlet is a Huawei compatible mini SC adapter, and the exit docking connector must be a mini-SC connector. The type of fibre optic cable to be docked depends on whether it can be matched to the connector. The advantage is that the connectors are already assembled at the factory and can be inserted directly on site to complete the construction, saving on termination labor and time cost. The disadvantage is that the lengths and specifications are fixed and require prior knowledge of the project details, while the front-end procurement costs are relatively high as the connectors and cables are expensive.

FDB Series (Fiber Distribution Box)

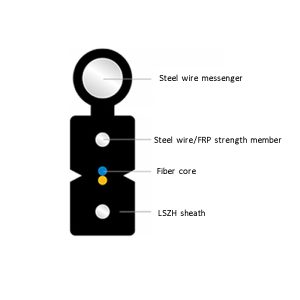

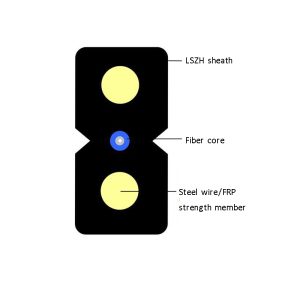

All ftth boxes on the market today are essentially for use with drop cable, so basically all of the products in this range have a drop cable outlet. There are slight differences in the style and diameter of the cable entry and exit in each box, but they are all similar in function.

FAT Series (Fiber Access Terminal Box)

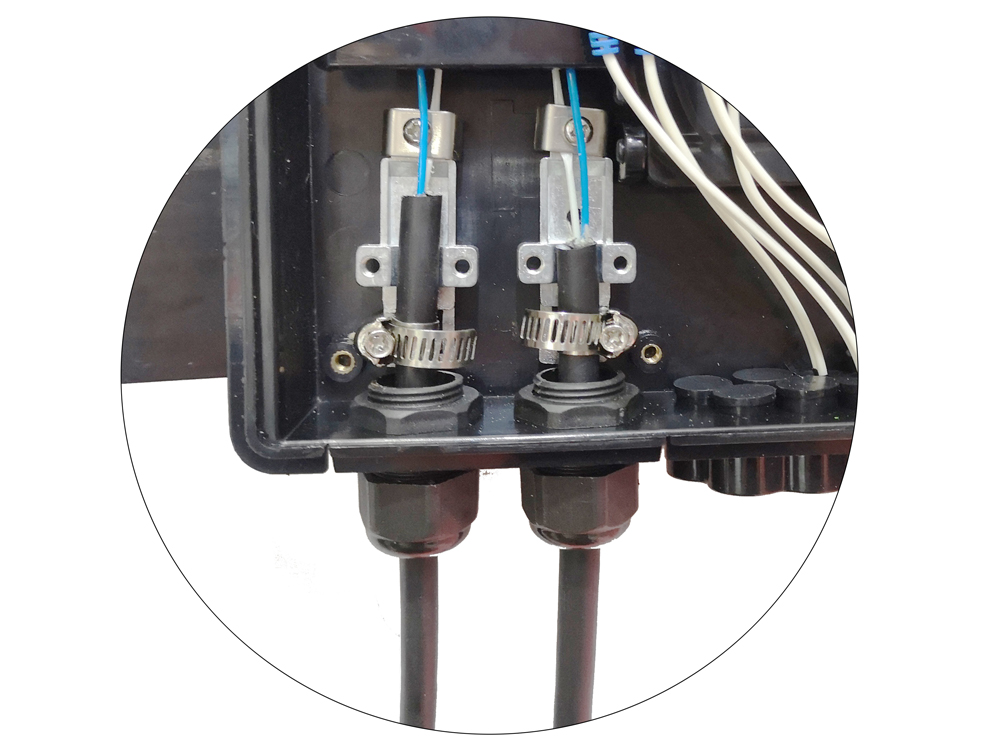

The distinctive feature of this series is that all cable outlets are fast connect waterproof plugs and the connectors for docking are normal SC connectors inside of the waterproof plug. There are no mandatory requirements or restrictions on cable type or connectors for docking, and the length of the fibre optic cable can be adjusted to suit the entire project. The advantage of this is that there is no need to plan the entire project in every small detail in advance, flexible and convenient to operate, which is also a big advantage for many phase 2 or renewal projects. The disadvantage is the increased construction time and labor costs in the field and the relatively lower efficiency.

Production Process

All of Yingda’s products are made of brand new raw materials and all production processes are in accordance with strict execution standards. All products are shipped after 100% inspection and passing. Refuse to inferior quality products and unqualified products to impact the market or damage the interests of customers.

Product Features

- Provide protection for connection of fiber optic cable and pigtails.

- Provide space for wiring and storage, easy to install and operate.

- With sufficient impact strength, easy installation in different use cases.

- Wall mount, pole mount, aerial mount available.

- All kinds of indoor cable, outdoor cable use, especially wide application for ftth drop cable

- Outdoor FTTH FTTB FTTD FTTC FTTA ,etc

- Connection type: SC LC with common type adapter.

- Made of high quality ABS PC PP+GF material

- Waterproof, moisture-proof, dust-proof, Anti-UV and other functionsetc

- Output port: 4 8 12 16 24 48 72 96 144Cores, with all kinds of waterproof connectors

Basic Functions

Fiber optic terminal box as the terminal equipment of fiber optic cable network, should have 5 basic functions as below: cable strength member like metal or kelvar fix and protection clamps, splicing for fiber pigtails or cables, optical distribution flat drop cable with fast connectors, optical splitter split light signal from 1 to 2 4 8 16…, and fiber access to store and winding in box, etc.

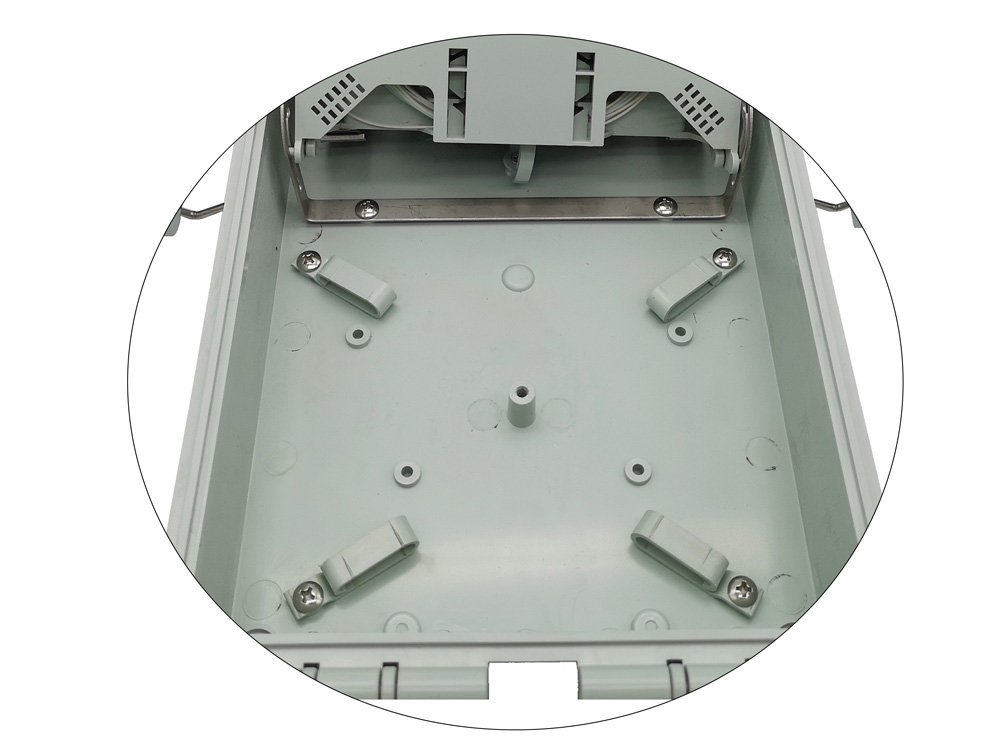

Fix & Protection

When the fiber optic cable is introduced into the cable distribution box, there must be a reliable fixing and protection device, and the fixed metal moisture barrier, armored layer and reinforced core of the fiber optic cable must be reliably connected to the high-voltage protective grounding device, and the fiber optic cable must be protected with plastic heat shrink protection sleeves or spiral tubes and fixed into the fiber optic fusion splicing device after stripping.

Butterfly cable coiling and tying must be natural straight, no twisting, ringing and other phenomena, it is appropriate to use the necessary fixed devices to ensure that no external extrusion and operational damage.

Splicing

At user side, can fusion splice the optical fiber cable with cables or pigtails, there is splice trays or splice plates in the distribution box, and the excess fiber is coiled and stored, and the fusion splice is protected and fixed with sleeves in the slots.

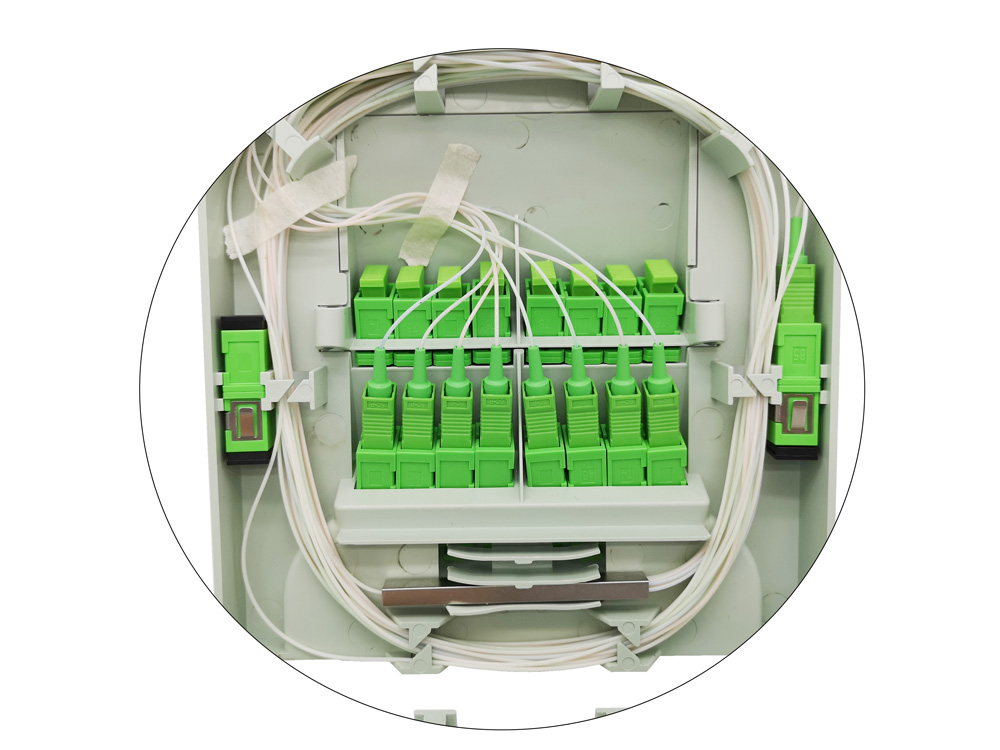

Distribution

There are adapter plates to realize achieve optical docking with the optical connectors at both sides. The adapter and connector should be able to plug and unplug flexibly; the optical path can be freely deployed and tested.

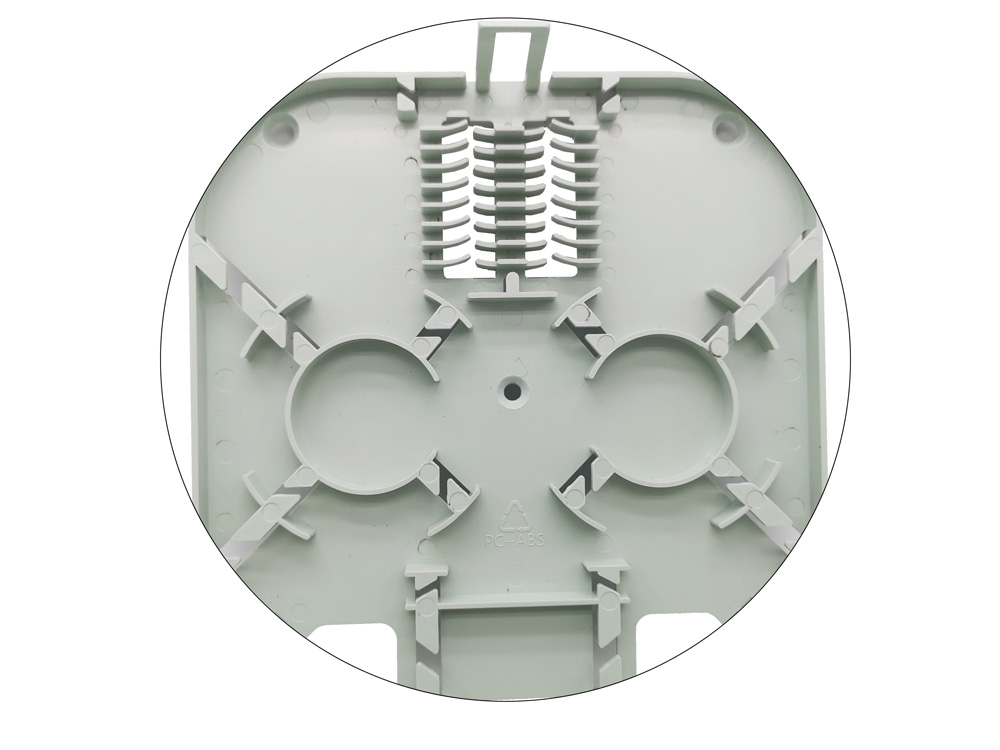

Storage

Every box is designed with enough and reasonable fiber storage area to hold the access fibers or cables and to ease cable wiring, adjustment, and can meet the minimum bending radius requirements.

Splitting

With the development of fiber optic network, the existing functions of fiber optic distribution box can no longer meet many new requirements. At present, fiber optic network components such as splitter, wavelength division multiplexer and optical switch are directly added to the fiber optic terminal box. There are mainly 2 types of splitters can be used, mini plc splitter or LGX module splitter.

Cable Entrance

Fiber optic distribution box mainly have 2 kinds of optical cable port design: uncut cable port (mid span or express port), waterproof glands.

Cable Exit

There are many types of cable exit in different shapes, size or functions. But the same function is to hold the cable exit in place and tightly during long run. Our company also named different product models according to this feature. The following mainly shows a variety of different optical fiber output you may meet:

Internal Structure

With the rise of fiber to the home, basically most of the boxes now highlight the splitting function, so the internal structure basically comes with a splitter function. And splitter is mainly divided into 2 types: mini splitter or LGX splitter module.

Mounting Methods

Outdoor optical distribution box mostly used in aerial mounted, pole mounted or wall mounted. Different box have different mounting methods, and the kits may differs a little. Please contact sales representatives for details.

Optional Accessory

However, on side construction installation will need other tools for different application, for example, after fusion splice, will need heat shrink protection tubes to protect the fiber joints, nylon ties to fix the cable in place, buffer tube to protect the bare fiber bundles from broken. Furthermore, there may need sleeve slots if there is no slots while need this function, adapter blocks to prevent dust, etc.

Free Samples Available

Only 2steps to get free samples from Yingda, help seize market share and win the bid in the fastest time.

Brand Improvement

In order to better enable our customers to improve brand awareness and expand regional influence, Yingda can print the brand, part number or other information that our customers need. So if you need, please share the original information in PDF. AI, CDR. or JFG formation, then will make for you. There are 2 types of printing methods, see below explanation:

Assembly & Termination

All fiber distribution box will totally enclosed with all accessories in carton box, 100% test before delivery. When customer get the box, only simple steps to finish assembly and terminated with fiber optic connectors to distribute light signals to end users.

FAT fiber optic box can install splitter, adapters, pigtails internal; outside is indoor or outdoor cable or drop cable with SC connectors or SC fast connectors; cable port is IP67 waterproof plugs.

CTO fiber optic box can install splitters, pigtails internal, not use standard adapters; outside use cables pre-terminated with Mini SC connectors ONLY. Cable ports are IP68 Mini SC adapters, the box waterproof grade can meet IP65 to IP68.

FDB fiber optic box can install splitters, adapters, pigtails internal, outside use indoor outdoor cable or drop cable with SC connectors or fast connectors, cable ports is round or flat ports. The box waterproof grade meet IP65.

Related Products

There are mainly several types of passive optical devices can be used in this optical distribution box: patch cord, adapters, pigtails, plc splitter, couplers, drop cable, fast connectors, heat shrink protection tube, etc.

- Fiber Capacity: 4core, 8core, 16core, 24core, 32core, 72core, 96core,… etc

- Adapter Quantity: SC LC ST FC, UPC APC or PC

- Pigtails: Connector type, fiber length, fiber type, etc

- PLC splitter: split ratio:1×2 1×4 1×8 1×16 1×32, … , pack in LGX ABS or Mini Type

- Print LOGO: where, what and size?

- Mounting Kits: wall mount, pole mount, aerial mount

- Color: White, black, gray or other

Possible To Change The internal To Other Type?

Yes, some models can, as long as the internal size and design is available. Please talk to our sales about which model can change. Take FDB0216H for example:

Can FDB Box Meet IP68?

Yingda have only a few distribution boxes can meet IP68, such as FDBF0216F, FDB0216F-S, FDB0224F, FDB0224G. which made test by SGS, this is waterproof.

Other boxes are mainly IP65 IP67 maximum, especially the box with drop cable ports, we only ensure it is IP65, it is only water resistant, not waterproof(at least IP67). If customers get quotation from supplier who said drop cable ports meet IP68, it is not true.

1. What is the difference of IP65, IP67 and IP68?

“IP” stands for Ingress Protection, and the 1st digits ’6’ describe the exact degree of protection against contact, the 2nd digit “5/6/7/8” describe the degree of protection against liquid.

2. Waterproof vs Water Resistant, What Are The Difference?

There are differences in the degree of water resistance, but there is no such thing as the degree of waterproof. That is to say, no matter how high the water pressure is, water can not seep in unless it is damaged, it is waterproof.

Do You Have Any Test Certification?

All of our products are made of brand new material, and our products have been tested by SGS environmental protection test report ROHS. To protect the environment, everyone is responsible.

If other test reports are required, we can cooperate with customers to verify within our own company or submit to third-party institutions for inspection. However, the customer must clearly inform the requirement in the order confirmation link. For different requirements, there will be slight differences in the ratio of materials used and the production process of the product. For example, flame retardant test, impact test, drop test, etc.

What Is The Best Material for FTB Box: PP ABS PC ?

Fiber optic distribution box is mainly used for outdoor installation, most now we make are high quality engineer plastic PC+ABS materials. In fiber optic industry, plastic mainly has three kinds:PC PP ABS or several kinds of plastic mixed materials.

- Polypropylene =PP

- Polycarbonate=PC

- Acrylonitrile Butadiene Styrene=ABS

ABS vs PC, Which Is Better?

Polycarbonate (PC) is temperature resistant, and somewhat flame retardant/self-extinguishing. Acrylonitrile Butadiene Styrene (ABS) is a blend of three different plastic materials – Acrylonitrile, Butadiene, and Styrene. When comparing, ABS vs Polycarbonate for patterns and colors, polycarbonate always wins. So at present, most fiber termination box indoor is ABS materia, PC is mostly used in fiber optic splice closure which used outdoors.

PP vs ABS, Which Is Better?

Some properties of ABS are the same as the PP’s. At the same time, ABS also has some other properties that PP does not have.

ABS is impact resistant, which is better toughness than PP. The temperature resistance of ABS is also better than PP’s. Both ABS and PP have shiny surfaces, and the surface of ABS is shinier than PP’s.

Is PC-ABS Stronger Than ABS?

PC+ABS is generally stronger than ABS, and provides higher impact resistance. In general, PC-ABS is up to 60% stronger than ABS in specific blends, having higher overall mechanical properties in most categories. Therefore, the most used is PC+ABS alloy material. This material is better than ABS alone, not so strong as PC. The price of raw material ABS PC PP tell the truth. However, with the increasingly competitive market and the serious impact of the epidemic on the world economy, the cost requirements are getting lower and lower, and currently many customers in the market can only accept the price of ABS material.

There are lower requirements market may choose PP instead, but from the life span and possible maintenance comprehensive consideration, Yingda still recommend ABS PC materials for all.