Fiber Patch Panel

Fiber optic distribution frame (ODF) is used for terminating and distributing fiber optic cables at the local end of the fiber optic communication system, which can easily realize the connection, distribution and scheduling of fiber optic lines. With the increasing degree of network integration, there are optical-digital hybrid distribution frames integrating ODF, DDF and power distribution units, which are suitable for small and medium-sized wiring systems from fiber to cell, fiber to building, remote modules and wireless base stations.

The most used products in ODF system is Fiber optic patch panel. Fiber patch panel is the interface panel that connects multiple fiber cables and optical equipment. Patch panels are rack-mountable onto 19”, 21”and 23” rack systems, and some are designed to be wall-mountable.

Features

- Metal cold rolled steel (SPCC) with spraying, thickness 0.8mm, 1.0mm, 1.2mm

- Indoor rack mount, wall mount application

- Front access only or both front and rear access

- Direct patching only, Direct splicing only or splicing and patching both

- Unloaded as a bare chassis, loaded with adapters only or loaded with adapters and pigtails

- Full range of fixed, sliding and pivoting patch panels are available

- Single fiber pigtails, ribbon pigtails or fan-out pigtails with feeder cables are available

- Fiber count from 12, 24, 48, 72, 96, 144, 288, ... 576cores can be optional

- Support all types of fiber optic connectors: SC LC FC ST E2000, etc

- 19" standard size, 1U, 2U, 3U, 4U, 6U & 9U and many more rack unit height are optional

- Configure all necessary installation accessories when delivery

- LGX module compatible

Production Process

YINGDA OFD Fiber patch panels offer an innovative and effective solution to meet your fiber optic connectivity needs. All fiber optic patch panels are made by TIA/EIA standards under ISO management system, all products ROHS, CE compliance. With automatic CNC machines and instruments, strict production policy and rich skilled workers ensure fast delivery time and large productivity every day.

Fiber Patch Panel Types

Fiber Optic Patch Panel can be divided by structure, interface or dimension, the most popular is categorized by panel structure:

ODF Rack & Cabinet

Fiber Distribution Unit

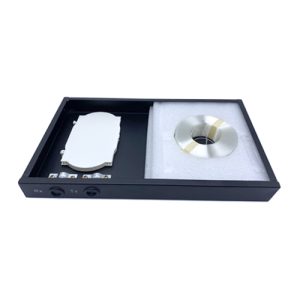

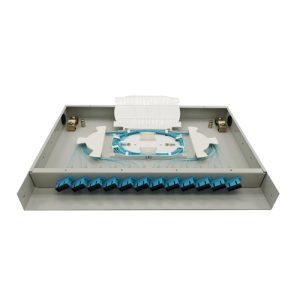

The ODF unit box shell is made of metal cold-rolled plate, and the internal sides are equipped with plastic sliding rails and integrated modules, which can be split, fused, stored and distribution in the modules. Fast convenient, quick connection, support pre-configure pigtail and splitter at the factory to save time and construction cost.

Fiber Patch Panel

This rack can also be purchased and configured separately, with fusion fiber trays, cable winding rods and fiber optic cable in/out fixing device, and the front panel can be configured with fiber optic cable fixing rods for terminal distribution. Fiber access can be top, front or back. Internal operation can be pulled out through the guide rail, fan out or top open the lid, the current drawer sliding type is the most convenient operation and the most used style.

Wall Mount Terminal Box

This type of terminal box is generally used in the building, floors with wall mounting holes. Some boxes are small, some are bigger.

Custom Service

Patch Panel Functions

Cable Fixture

Cable Termination

Fiber Location Change

Identify

Fiber Storage

Fusion Splice

ODF Spare Parts

Accessory will include mounting expansion screws, fixing screws, cable clamps, nylon ties, label mark, heat shrink protection tubes, mounting ears, etc.

If need more accessory, please contact our sales team now!

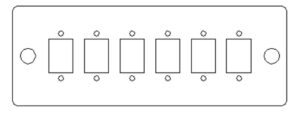

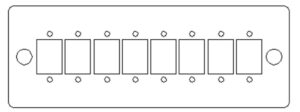

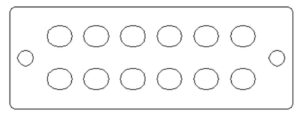

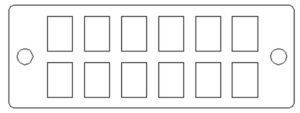

Variety of Connector Interface

Different fiber optic connectors can be used on the front patch panel, SC LC ST FC, E2000, MPO, etc. The port can be simplex or duplex.

- SC outer size is square and the same as LC duplex, so if SC simplex port can use for LC duplex adapters, SC duplex hole can use LC quad adapters too;

- FC and ST adapter outer size is round and the same, so they are universal.

Patch Panel Cable Port & Splicing Capacity

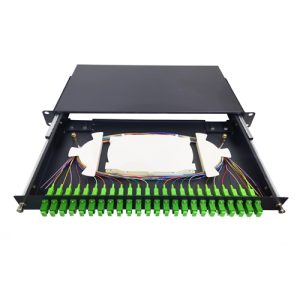

Port is the adapter quantity on the front panel, 1 port= 1 hole=1 adapter, normally 12port, 24 port, 48port, 72 port, 96 port, 144 port, etc. 1U rack normally max can do 24 ports for pigtails or patch cord. If use for PLC splitter, it can max. do 33 ports or 34 ports, that is 1×32 PLC Splitter or 2×32 PLC splitter. 2U can do 48 ports, 3U can do 72 ports, 4U can do 96 ports.

Capacity is single fiber quantity which can be fusion spliced in the patch panel in total. It most of the time depend on the splice trays, where how many sleeve slots means how many fibers, if the slots is high to contain 2layters of sleeves, then the fiber count can be double. If the path panel have 2 pcs splice trays in total, each tray is 24cores, that means the patch panel capacity is 2*24 cores=48 cores patch panel.

Generally, the adapters quantity will be the same as fiber count, but if adapter is duplex, then fiber count shoudl be double, and splice tray is normally 24cores for patch panel. For example:

48 port Patch Panel SC duplex fully load will be: 48 pcs SC duplex adapters, 96 pcs SC pigtails, 4 pcs 24 cores splice trays.

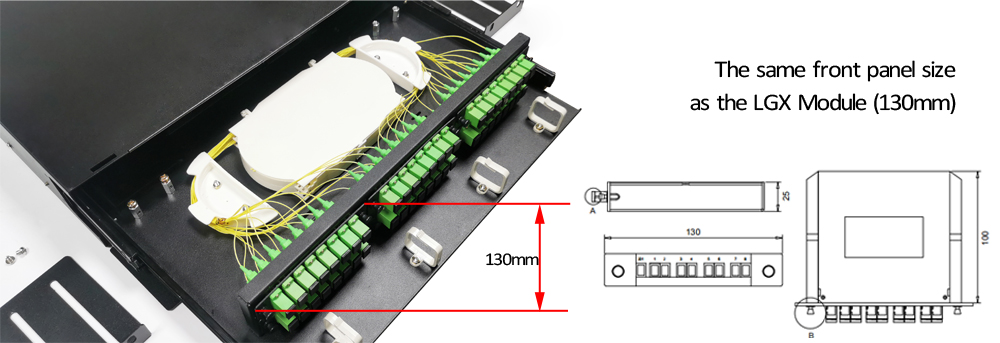

Adapter Panel and LGX Panel Interchange

The adapter panel in front panel can be clip type, pull in and out by the rivet. Normally 1U can hold 3pcs 8SC port adapter panel, 2U hold 6pcs 8SC port adapter panel, 3U hold 9pcs 8SC port adapter panel. And the adapter panel front size is the same as the LGX module (cassette) which is for 1×8 splitter module. So it can add one more function splitting for the same fiber optic the path panel except fusion splicing, storage, management, or winding functions.

Fiber Patch Panel Quality Assurance

Appearance Requirements

- The commonly used rack is 19 inches, with the ears on the left and right side to fix the rack to the ODF, the spacing are common worldwide. 21 inch and 23 inch are available, also wall-mounted.

- Mechanical moving parts should be flexible in rotation, moderate in plugging and unplugging, reliable in locking, easy in construction installation and maintenance. Can open the door in front or behind, or no door setting.

- Introduction of fiber optic cable into the rack, the fiber bending radius should be not less than 15 times the diameter of the fiber optic cable.

- Rack structure should be solid, the assembly should be consistent and interchangeable, and the fasteners are not loose. Exposed and operating parts of the sharp edges should be rounded.

- Fiber optic cable through the metal plate hole and along the sharp edges of the structural parts of the turn, should be equipped with protective sleeves and padding. Fiber core, pigtail wherever bending, the radius of curvature should be not less than 30mm.

- The surface of the rack should have a coating layer, and the coating layer should have a clean surface, uniform color, no hanging, no bottom; metal parts without burr rust.

- Structure device on the text, graphics, symbols and signs should be clear, complete and error-free.

Material Requirements

1. Anti-corrosion performance

ODF all parts used in the material should have anti-corrosion properties, if not, will do anti-corrosion treatment; its physical and chemical properties must be stable and compatible with the fiber optic cable jacket and pigtail sheath. To prevent corrosion and other damage, these materials must also be compatible with other materials commonly used in equipment.

2. Anti-rust properties

Plating treatment of ODF surface metal parts, after 48h salt spray test, the appearance shall not have rust spots visible to the naked eye.

3. Coating treatment requirements

The metal parts is with coating treatment, the coating and the substrate should have good adhesion, adhesion should not be less than GB/T9286 standard: at the intersection of the cut and/or along the edge of the cut, if there is the coating off, the affected cross-cut area is significantly greater than 5%, but not significantly greater than 15%.

4. Combustion performance requirements

Equipment in the non-metallic materials of structural components and fiber optic connectors should meet one of the following conditions of combustion performance.

(1) the test sample did not ignite.

(2) the test sample from the fire after the continued flaming time of no more than 10s, and the flame or burning or scorching particles falling from the test sample did not make the combustion spread to the bottom layer placed under the test sample.

Frequently Asked Questions

What is a fiber patch panel?

Fiber patch panel is a jumper connection and distribution panel, which mainly realizes the optical fiber wiring and distribution and storage functions through some preset optical fiber interfaces, optical fiber fusion splice trays, optical fiber management unit, etc.

What is the difference between copper patch panel and fiber patch panel?

Copper patch panel is used for Copper structured cable such as cat5 cat5e cat6 cat6e cat7, etc with RJ45 connectors. But fiber patch panel is used for fiber optic cable with connectors SC LC FC ST,E2000, MPO, etc. There are more and more fiber optic patch panels with the high speed transmission demand.

How many ports can a patch panel have?

Patch panel can be 1U 2U 4U 6U …etc. 1U patch panel can maximum do 48 cores SC, 96 cores LC, 576 cores MPO multi fibers connectors. If the patch panel is higher, the capacity will be larger accordingly.

Can you ODF meet IP65?

Not all of ODF can meet IP65. If ODF outdoor cabinets, it can meet IP65 with waterproof rings internal all sides. But most of the ODF or patch panel are used indoor wall mounted or rack mounted, so it is only dust-proof.

What is the difference between patch panel and patch cord?

Patch panel is rack mounted panel with adapter plates on front for fiber access in front or rear sides, it mix cable distribution, management, patching storage in one unit. But patch cord is only a passive optical device with 2 connectors on both sides of fiber optic cable. Patch cord can be used in patch panels.

A-300x300.jpg)