Splice Sleeves

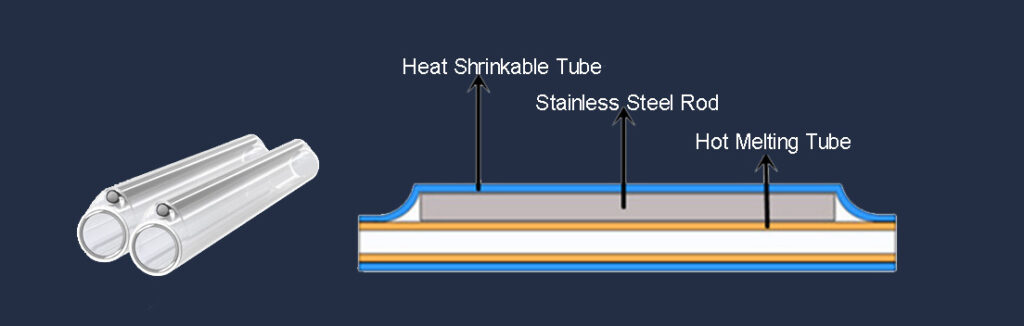

Heat shrinkable optical fiber splice protection sleeve is a specially designed optical fiber connection protective element consisting of PE heat shrinkable tube, hot melt tube and reinforced stainless steel needle.

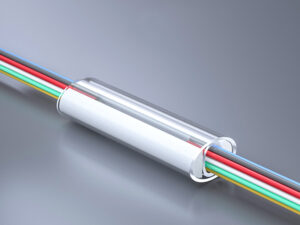

When the optical fiber is connected by the fusion splicer, will strip the cable outer sheath and protective layer which make the fusion point vulnerable to external influences and reduce the mechanical strength accordingly. Fusion splice protection sleeves used with a degree of rigidity can provide vital protection at the fused juncture between two fusion spliced optical fibers and prevents the spliced area from bending or flexing, the sealing structure makes the connection good resistant to temperature and humidity.

The fiber splice sleeves are widely used in fiber optic telecommunication equipment like fiber optic splice closure, cable termination box, optical distribution frame,cabinets, optical distribution box, etc.

Features

- Operating temperature: – 45~100 ℃; Shrinkage temperature range: 110 ℃.

- REACH & RoHS compliant.

- The optical conductivity of the optical fiber is maintained.

- Protect the connection points and improve the mechanical strength.

- Transparent case makes the connection of optical fiber clear at a glance.

- Simple operation, reducing the risk of damage to optical fiber during installation.

- The sealing structure makes the connection have good temperature and humidity resistance.

Production Process

Fiber optic sleeves are strictly produced and controlled by industry standards and ISO management system. 100% check and confirm in good condition before delivery.

- Prepare raw materials: heat shrink tube, hot melting tube, stainless steel

- Steel cutting, grinding, polishing, cleaning and drying

- Assembly steel needle, tubes by automatic machines, forming and chamfering

- Quality check, sub-packaging, labeling, final packaging and warehousing

Full Range Production

Single fiber sleeve, ribbon sleeve, drop cable sleeve; side shrink, full shrink; one ceramic rod, two ceramic rods type…

Sleeve Category

Yingda offer many types of sleeve: single fiber, ribbon fiber, drop cable, micro fiber, etc. The structure are a little difference, but the same function.

Type 1: Single Fiber Splice Sleeve

Single fiber splice sleeves are mainly used for bare fiber 250um, and the popular length is 40mm 45mm 60mm. But Yingda can do wide range length from 10mm to 61mm. The strength member is stainless steel, it can be 1pc or 2pcs, the most popular is 1 steel needle, the diameter Yingda can do is from 0.5mm to 1.5mm. According to the diameter of steel, it can divide into different models, like 40*1.0mm, 45*1.0mm, 60*1.0mm. Download our catalogue for more information.

Type 2: Ribbon Fiber Splice Sleeve

Ribbon fibers heat shrinkable protection sleeve are widely used to protect the ribbon fibers like 6core, 8core, 12cores. The strength member internal is ceramic rods instead of stainless steel, which ensure long lasting and good protection for ribbon optical fibers. It can be single ceramic rod or dual ceramic rods. The cost and performance differs according to customer requirements. Also welcome customize according to customer request.

Type 3: Drop Cable Splice Sleeve

Drop cable splice sleeve mostly used is 60mm length, it can use 1piece stainless steel or 2stainless steel for strength member. Both type are popular, which is widely used in FTTH network direct fusion, which is High temperature resistance and long service life. Both ends are chamfered and sealed, and the steel needle is not easy to fall off.

Free Samples Available

Only 2steps to get free samples from Yingda, help seize market share and win the bid.

How To Use The Fusion Sleeves?

The optical fiber heat shrinkable tube plays an important role in the optical fiber backbone network due to its excellent performance. How to use the optical fiber heat shrinkable tube is particularly important for users. There are mainly 5 steps, taking the fiber optic splice closure as an example.

During the operation, rotate the sheath cutter and pay attention to the cutting. When white polyester tape is seen, stop feeding and remove the cutter.

After stripping the outer layer of the optical cable, it is necessary to fix the optical cable in the splice closure. Strip the core tube. Prepare for optical fiber fusion. In addition, it should be noted that:

- Core bundle tube shall not be twisted. Before fixing the optical cable, pay attention to the position of the fiber core bundle tube. When the stiffener passes through the fixing screw, the lower part of the stiffener must be a filling bundle tube, not a fiber core bundle tube. The fiber core bundle tube must be on the same side of the stiffener entering the optical fiber receiving tray, and cannot be twisted on the stiffener.

- The length of reinforcement shall be appropriate. After the position of the fiber core bundle tube is determined, the optical cable can be fixed.

- The stripping length of fiber core bundle tube shall be appropriate. After the optical fiber is fixed, the fiber core bundle tube can be peeled. If the stripping length is too long, it will reach the groove of the optical fiber heat shrink tube, and the residual fiber will be damaged when the fiber is coiled; If the stripping length is too short, when the fiber core bundle tube is fixed, the fixing clip will be stuck on the optical fiber, which is easy to damage the optical fiber.

Therefore, it is generally advisable to peel it over two fixed bayonets, and the fiber core bundle tube of this length will not cause stress damage to the fiber, but also can be fixed well. However, the clamp of optical fiber heat shrinkable tube shall not be too tight when fixing, otherwise the optical fiber of the fiber core bundle tube will increase loss due to stress, and the optical fiber will break after a long time, leaving a hidden danger for the project.

The connection of optical fiber directly decide the quality and life of the project, and the key is the optical fiber end face. If end face r is smooth and free of burrs or defects, the fusion splicer can be well make joints with good performance. If the end face is unqualified, the fusion splicer will refuse to work, or the joint loss is large, which does not meet the engineering requirements.

Fusion Splicer is the key equipment of optical fiber welding, and it is also a kind of equipment with high precision and high price. In the process of use, the operation must be strictly in accordance with the regulations, otherwise it may cause heavy losses. Special attention shall be paid to the operation procedure, and the length of the optical fiber heat shrinkable tube shall conform to the requirements.

After the optical fiber is spliced, not only the optical fiber shall be protected by heat shrink tube, but also the residual fiber shall be coiled.

- In the process of fiber winding, the bending radius shall not be too small, generally not less than 4mm. Or else it is easy to cause excessive refraction loss and increased dispersion. Fiber breakage may also occur after a long time.

- When coiling, pay attention to the twisting direction of the optical fiber, which is generally an inverted “8” shape. Pay attention not to twist the optical fiber. After coiling, put all the optical fibers under the baffle of the receiving tray to avoid damage to the optical fiber during packaging.

In the actual cable distribution project, the sealing of the optical cable splice enclosure is very important. Because if the closure is flooded, there may be tiny cracks on the fiber surface, if it is soaked in water for a long time, the optical fiber will break. Furthermore, most fiber optic splice box are buried underground, so the sealing is very important.

Package Information

- Sleeve type: bare fiber sleeve, ribbon fiber sleeve, drop cable sleeve

- Tube length: 10mm, 15mm, 20mm ,25mm, 35mm, 40mm, 45mm, 60mm, 61mm

- SS Steel size: 0.5mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm

- Quantity: 1000pcs, 10000pcs, 100000pcs

- Custom:Sticker information, silk print, delivery time request, etc.

Frequently Asked Questions

With more than 10 years fiber optic experience, we help solved many problems or questions. Trust us, you are not alone.

What Is The Lead Time Of Sleeve?

Our factory is large capacity, full production every day. If standard bare fiber splice protector, only final pacakge with stickers, 1 – 2days is ok. If mass production, will do about 5 – 10days according to the bulk order quantity.

What Size Of Protection Sleeve Used For Single Fiber?

The popular length is 40mm, 45mm and 60mm, if customer not specify, will configurate 1.0mm steel rods. If used in compact size fiber optic box or splice closures, suggest to use 40mm, if enough space, suggest to use 45mm or 60mm for better protection.

Can Do Colorful Heat Shrink Splice Protector?

Of course. Colors can be customize if meet MOQ. Please talk with our sales representatives for details.

Can You Silkprint LOGO On Fiber Sleeve?

Yes, we do. Please share us your original file, we will do accordingly. It may add a little cost on the product itself, please kindly understand and support.

What Is The Material Of Stainless Steel?

Yingda sleeve fiber optic are all made of stainless steel. There are two types of commonly used stainless steel plates, 201 and 304. In fact, the composition is different. 304 is better in quality, but the price is expensive. 201 is worse. 304 is imported stainless steel plate, 201 is domestic stainless steel plate.

201 Stainless Steel

- 201 is composed of 17Cr-4.5Ni-6Mn-N, which is a kind of Ni saving steel and a substitute for 301 steel. It has magnetism after cold working and is used for railway vehicles.

- 201 is characterized by high manganese content, bright surface with dark light, and high manganese content is easy to rust.

- Because the nickel content of 201 is low, so the price is much cheaper.

304 Stainless Steel

- 304 is composed of 18Cr-9Ni, which is the most widely used stainless steel and heat-resistant steel. It is used for food production equipment, general chemical equipment, nuclear energy, etc.

- 304 contains more chromium, the surface is matt, and does not rust.

- 304 is expensive now, but 304 can at least ensure that it will not rust during use. (Stainless steel medical liquid can be used for experiment)

How To Distinguish 201 & 304?

There are many identification methods, such as authoritative agency testing, spectrometer testing, grinding spark state judgment, magnetism, etc. However, some methods are too costly and some methods are inaccurate. Hereby Yingda recommend that customers use the most economical and effective way to judge by dropping liquid medicine on steel surface and check by human eyes.

Usage method:

- Make sure the steel surface is clean without oil stain, and the coating is removed.

- Drop one liquid on the steel surface and observe the color change. After 2-3 minutes, compare the color or reddening time to confirm the stainless steel model.

Test Results:

- 201: Turn red in about 50 seconds, Manganese exceeds the standard

- 202: Turn red in about 1minutes, Manganese exceeds the standard

- 301:Turn red in about 2-3minutes, color is very light, should look carefully. Manganese exceeds the standard

- 304:No red, turn brown or discoloration within 3minutes.

- 316:Change from light green to black brown in 3-5 minutes.

***The faster it turns red, the worse the material!

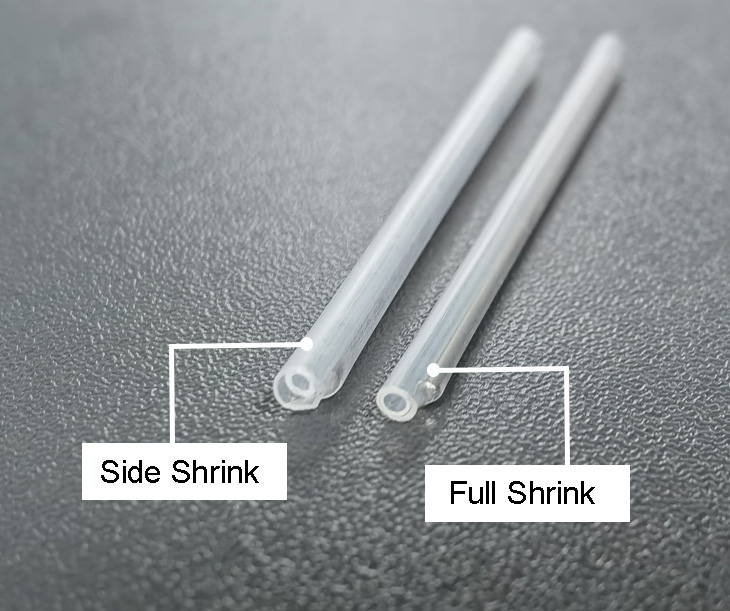

Can You Do Full Heat Shrink Sleeve?

Certainly yes, we make and export a lot of full shrink sleeve every month, and have deep experience in this field.

Full heat shrinkable tube, also known as pre-shrink tube, has the following characteristics and advantages compared with the conventional side sealing heat shrinkable tube. After fully shrink, the heat shrinkable tube component Fully integrated, closely integrated, to prevent parts separating, good appearance.

Side sealing shrink in the fusion process will have some problem like bubbles, uneven shrinkage and other problems which cause fiber loss and affect optical transmission! Full shrinkage is effective to avoid this problem;

At present the full shrink tube can be made as follow specification, after shrinking diameter 3.0,2.6.2.5,2.4,2.0,etc. Standard and micro heat shrinkable tube temporarily unable to complete contraction; the length can be customized according to customer requirements

*** Full Shrink vs Side Shrink, What Are The Difference ?

The most difference between the full sealing type and common type (side seal type) is the processing technology of both end closing.

Full sealing type adopt full range of pre heating shrinkage technical to achieve the seamless between inner and outer of both ends of the tube.The steel needle is fixed in the middle.Much neater and good appearance. Quality is as good as Tyco SMOUV.

Ordinary type adopt the side heat shrinkage, there is a gap between the inner and outer tube of both ends, unattractive.

Can Make Micro Sleeve 25mm Or 15mm?

Yes, we do. Due to the smaller, the steel size is smaller, and it is hard to do by machines, so the production time will quite depend on the human, so delivery time is much lower than the normal types.

How To Control Fiber Sleeve Quality?

Under ISO management system, all our products materials and finished products meet ROHS standards. For raw materials, all brand new PE material for the outer tube, EVA material for inner tube, and 201 or 304 for the steel rods. There are factories who make inner tube with PE materials, or the production environmental is not clean, the final products will be non-transparent, or there are many dirty or black spots attached to the product.

Furthermore, our product engineer with more than 15years production experience, all our products are made by self-developed production equipment, which ensure to adjust and correct various details and errors at any time. Our heat shrink tube cutting end face is very neat, and the inner and outer tubes are basically aligned. Many incisions on the market are uneven, and some inner tubes are longer than the outer tubes, their quality control is very poor.

Before package, will check all items one by one to make sure there is no unqualified sleeve before package.

And we always prepare a certain amount of spare parts for each large order to prevent the client from being lost or make up for the risk that it cannot be supplemented.