Fast Connector

Fast connector is short for fibre optic fast connectors, it is a kind of field-assembled fibre optic movable connectors, widely used in the building, fiber to the home and other fiber optic cable deploy environments for optical cable termination.

International standards:GR326, IEC61300-2, ROHS, IEC61754-4, IEC61753-1 standards

Wide Application

Fast connector fiber optic can be adapted to a wide range of deploy environments without the need for other forms of protection and with extremely low loss to the optical signal, it is an important guarantee for FTTH fibre optic network. In particular, the SC fast connector is widely used in field cabling and FTTH because of its high success termination rate and high stability.

Fast Connector Production Process

Fast Connector Category

According to different type of interface , connector can be divided into several types: SC LC FC ST. Due to FTTH network and Data Center network are very popular, now SC fast connector and LC fast connector are quite hot sale, each one have many types of versions.

Fast Connector Features

- The pre-embedded fiber is factory polished and filled with matching oil at the docking area, not rely too much on the fiber cut flatness, greatly reducing the requirement for operator proficiency.

- As the end face of the splice is pre-grinding and pre-polishing, insertion loss will be less than 0.5dB and return loss will be above 45dB, it is more reliable and stable, suitable for FTTH access network and indoor node field installation.

- Termination no need special operating tools like fusion splicer, easy to operate.

- Fast on connector is small size, light weight, fast termination about 1 ~ 2mins.

- Various fiber optic connectors are international standards, fully compatible with various standard fiber optic adapters an d interfaces SC LC FC ST,etc

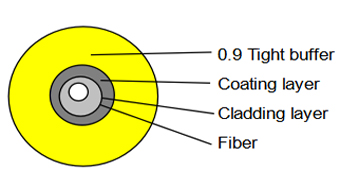

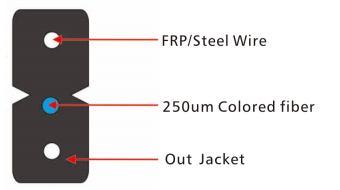

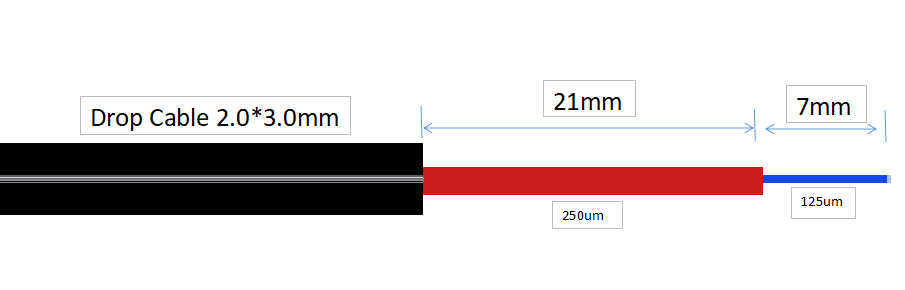

- Suitable for many types of cable, like 0.9mm tight buffer, 2.0mm 3.0mm soft indoor cable,and figure-8 drop cable 2.0x1.6mm 2.0x3.0mm directly terminated.

- The connectors can be reused, simple and convenient, easy and fast maintenance.

- In very challenging environments such as utility poles or access holes, the connectors can be self-connected on site, reducing connection error rates and saving time and labour costs.

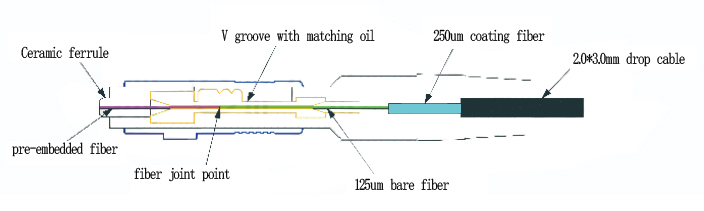

Working Principle

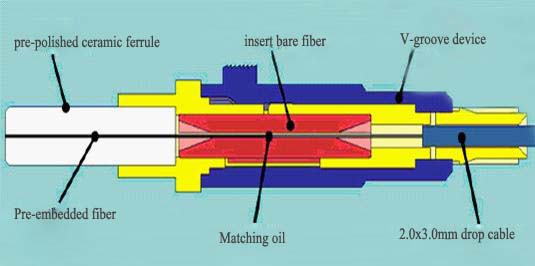

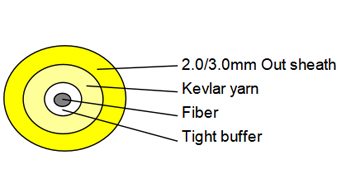

Fiber Optic Fast Connector is a pre-embedded fibre structure, where a section of bare fibre is pre-inserted into the ceramic ferrule core at the factory, and the ferrule end face is grounded and polished, the docking area is filled with matching oil; when on-site construction, the operator cuts the feeder cable sheath, strip the coating till bare fiber and then insert into the V groove device, fix the fibre and the pre-embedded fiber in a high-precision V-groove to achieve a seamless docking between the fibre cores by means of outer diameter alignment.

Spare Parts

FTTH Fiber Fast Connector is made from plastic materials, the main parts include: Dust cap, V groove, cermic ferrule, spring, mai body, housing, and screw nut.

All raw materials are brand new, no second hand, all meet RoHS standard, and test 100% qualified. All spare parts will be assembled at factory and test 100% before delivery, quality assurance, and fast delivery time.

Applicable of Cable

Package Information

Yingda provides all kinds of package methods for customers, like PP bag, blister box, candy pack or others.

PP Bag

Carton Box

Collation Ferrules to Molds

Blister Box

Carton Box

Collation Ferrules to Molds

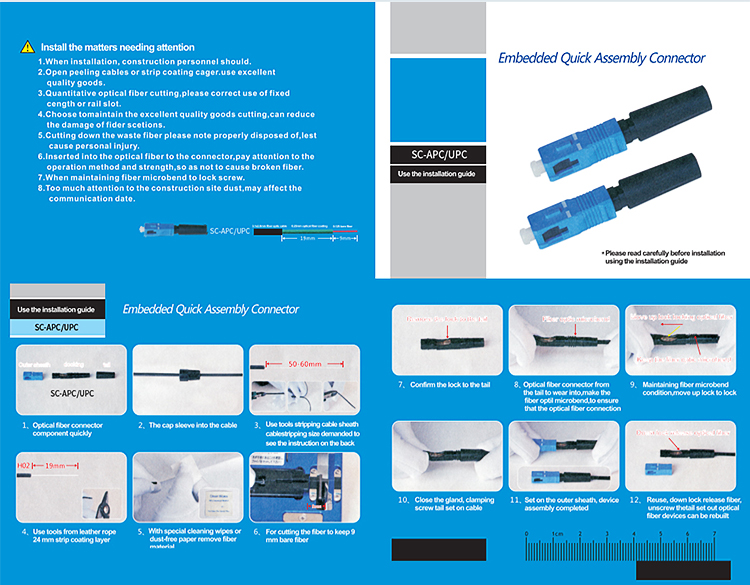

How To Connect Fast Connector With Fiber Optic Cable?

Fiber optic fast connector installation is very easy, but it is highly susceptible to contamination and damage resulting in damage to the performance of the fiber, in the installation process should be away from dust and contaminants, and inserted fiber slowly to prevent fiber from broken.

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Step 7

Notes

Standard Configuration

Every fast connector will configurate English user manual, length fix tool especially. Please do read the manual carefully and operate according to the manual.

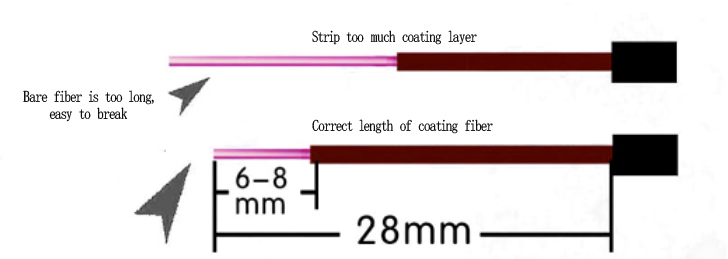

There are bare fiber/cable coating length data on each manual to guide customers, pls take note.

Every type of connectors will use different manual or length fix tool, but if your are skilled workers, then no need manual or any kind of tool can be used, only refer to the length, it will be done.

Tools Needed On Site Construction

Dust free paper Kimwipes, alcohol (alcohol cotton), Drop cable stripper, Miller coating stripper are the necessory tools which needed on sit construction, you can buy in your local market, or contact us.

Besides, for better operation, suggest to use ftth toolkits bag as below:

Before Buying, Please Help...

If you are interested in our products, please help send the following information, so that the sales representative can reply to the quotation in time.

- Connector type: SC LC FC ST

- Polish mode: UPC APC

- Connector length:50mm 52mm 53mm 55mm 60mm,etc. (Note: length is from the ferrule top till the boot end, not including the dust cap.)

- Insertion loss:<0.5dB, or 0.3dB

- Pack: PP bag, blister box, or custom

- Applicable cable type:900um 2mm 3mm 2.0*1.6mm 2.0×3.0mm

1. Why The Test Data Greater Than 0.5dB?

Before test, ensure the equipment is normal and the test data is cleared. Excluding product quality problems, normally caused by manual operation errors. Please reconfirm whether to follow the manual operation steps? If not, please follow the steps step by step to operate again.

If the parameter is large like 20dB, that means the 2 fibers are not aligned at all, maybe the fiber is broken during operation, the fiber is not long enough or the fiber is not inserted correctly.

If the parameter is not large, like around 1dB, there may be several cases as follows, please eliminate one by one to find out the problems.

- The inserted bare fiber is short, please follow the length indicated in the manual to cut. Do not cut manually or by scissors according to visual inspection.

- The cutting knife surface is worn or the fiber is not put in place, the fiber slides when cutting, please change the knife surface to cut or pay attention to the details of the operation. Recommended to use a high precision cutting knife to ensure the cutting end surface is complete and smooth.

- The fiber is not cleaned after cutting, there is oil and dust on the end face, please clean it with dust-free wipes lightly.

- When inserting the fiber, the cable must be slightly bend, and then lock the fiber after tightening the nut, otherwise the fiber will slide leading to poor contact.

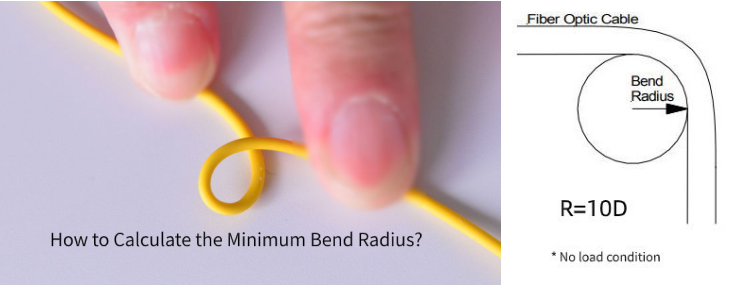

- The use of space is too small, such as ONU, the general internal space is very small, it is best to use 50mm connector but with 60mm fast connectors. After installation, the limited space will result in very large curvature ratio and much attenuation loss. Sometimes there are many cables and connectors in a chassis, the situation is more serious. Especially on 1550nm wavelength test data will be more obvious.

2. Why Does The Fiber Break?

Improper operation like fiber cutting length is too long, more than the specified length which is not seen until the fiber bend has broken.

Strip too much the coating layer, lost the protection of the fiber, due to the fiber bend too much. Therefore, please strip the fiber with length fix tool.

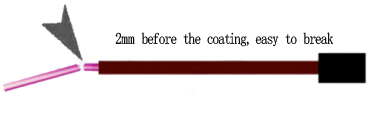

When stripping the fiber with pliers, the fiber is injured at 1-2mm before the coating layer, which cannot be seen by the naked eye. When subjected to external vibration, the fiber is broken. Recommended to use high quality stripping pliers or regularly check whether the blade is damaged and replace it in time.

3. Why Is The Signal Bad After A Period Of Time?

If the customer destination has special environmental, such as perennial high and low temperature environment, recommended to use metal V-groove or ceramic V-groove ferrules, because these 2 materials will not thermal expansion and contraction lead to fiber deformation or damage. Commonly used plastic V-groove is easy to thermal expansion and contraction, resulting in fiber will be squeezed deformation and signal attenuation.

4. Why Can't Insert The Fiber Into The Fast Connector?

- The fiber optic switch is not turned on. Before shipment, we will turn off the fiber optic switch after testing to prevent dust or spoil and matching liquid from evaporating. So you must open it manually when you use it.

- There are broken fibers inside the built-in V-groove, occupying the fiber channel. Confirm whether the worker made a mistake in the last operation? If it is the first operation, the fiber is also not broken, it should be left broken fiber after test at factory, which the staff did not notice and delivered.

- The fiber is not properly inserted into the guide slot of the connector.

5. How Long Of Fast Connector Should I Choose?

According to the actual use scenario of this product, choose different lengths of fast connectors to ensure that the bending radius of the fiber optic cable is within the normal range. Generally, pre-embedded is G65A71 fiber, the bend radius ≥10mm.

6. Why The Fast Connector Attenuation Will Become Large or Not Conductive After Some Time Use?

- Not using specified fiber cleaver or blade damage, the cutting end face is serious abnormalities (fusion splicer can check the end face) . Initially light temporarily conductive by matching oil, over time matching oil gradually detaching from the end face, resulting in the line gradually disconnected. Solution: Try to re-cut the fiber and reassembly, but if connector have broken fiber, the problem may not be completely solved.

- The used drop cable shrinkage rate is too high to accept, especially the occurrence of high rate of hot and humid season. Unscrew the connector nut to check, if the optical fiber micro-bend no longer exists, that is caused by this reason. Solution: Do not hanging the extra fiber optic cable outdoors, try to shorten the exposed cable, re-cut the fiber, slightly increase the fiber micro-bend, try to tighten the nut, the problem can be solved.

What Is The Difference Between Fast Connector And Mechanical Splicer?

Mechanical splicer is the same structure as fast connector, outer appearance are similar, but it does not have movable interface / connectors. When connection fiber and fiber or fiber with pigtails, it make direct fixed connection at optical link node, the junction loss of about 0.1dB ~ 0.2dB. It is more convenient and flexible in indoor wiring or limited space deployment.

What Is The Difference Between Fast Connector And Fusion Splice-On Connector?

Quick connector is generally divided into two categories of mechanical and thermal fusion. Mechanical is also divided into pre-buried and through type.

Pre-embedded Fast Connector

Fast Connector pre-buried a section of optical fiber from the ferrule top to the connector internal V groove. On site construction, will insert cable into the V groove to realize connection through the matching oil. This method is commonly known as cold splicing.

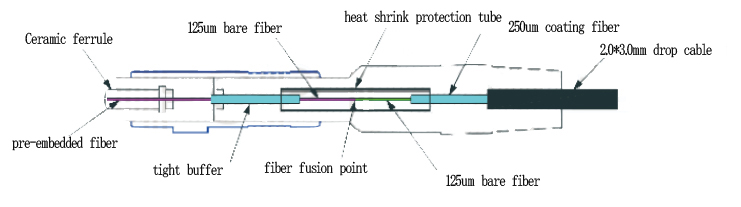

Fusion Splice-On Connector

Fusion splice on connector also pre-buried an optical fiber in the connector, and connection is fusion splice, but the fusion joint is inside of the connectors. On site construction, remove the connector boot, strip and cut the tight buffer, then fusion with the end of the fiber optic cable on fusion splicer. Fusing fiber with a fusion machine is commonly known as thermal fusion, which is a high-voltage discharge to fuse cut fibers together.

Fusion Splice On Connector

Yingda can offer all kinds of fusion splice on connectors on customer request. It is widley used in FTTH network too. All will be test 100% before deliery, and package well. Now most buying is SC fusion splice on connector and FC fusion splice on connector.

Comparison

Fusion splice on connecctor is the same as traditional fusion, need fusion splicer. It is a high quality operation, low splice loss (generally 0.03-0.05dB), the loss will not increase with time. But fusion splicer is high cost, complicate to operate, limited power storage capacity, field operations are limited. So this type of connector application is less.

Pre-embedded fast connector is a cold connection, the pre-buried fiber has been pre-grinding and polished in factory, end-face optical properties is basically the same as the conventional patch cord connectors. And its connection through the matching oil, the assembly operation requirements are not so stringent. Because it does not require a fusion splicer, pure passive construction operation, fast and convenient, no need special tools, easy to carry, suitable for field operations. The disadvantage is the loss is larger than splice on connectors, generally 0.2-0.5dB per cold joint.

Overall, cold jointing need less tools, but the price of the connectors need cost, which is relatively expensive than fusion splice. But hot fusion requires splicer machine which is expensive and not easy to carry. Cold jointing loss is greater than hot fusion. So please choose according to your project needs and real situation.