Description

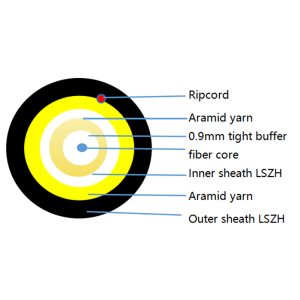

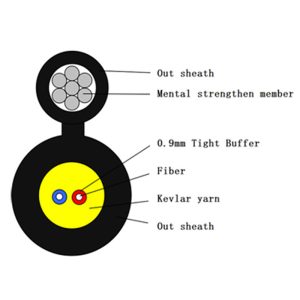

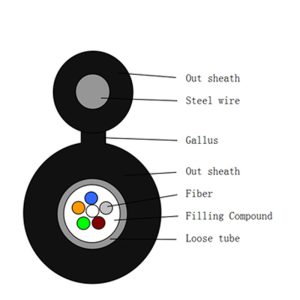

Bow-type FTTH drop cable is with optical fiber in the center, and 2pcs parallel KFRP/GFRP or kelvar strength member are placed at the two sides. The duct drop cable is with the same structure inside and with aramid yarn and additional strength members to protect the fiber unit inside, finally wrapped with PE sheath and ripcord for easier cable stripping.

Duct Drop Cable Application

- Adopted to outdoor level and vertical distribution.

- Suitable for aerial and duct drop installation

- Long distance and local area network communication.

Duct Drop CableFeatures

- Good mechanical and environmental characteristic

- Anti-UV characteristics meet the requirements of relevant standards

- The mechanical characteristics meet the requirements of relevant standards

- Big capacity data transmission

- Meet various requirements of market and clients

Duct Drop Cable Parameters

| Item | Value | |

| Number of fiber | 2 cores / 4 cores | |

| Fiber type | G657A2, G657A1, G657B3, etc | |

| Strength member 1 | material | KFRP / FRP/ GFRP/ Kevlar / steel wire |

| diameter | 2*0.5mm | |

| Strength member 2 | material | FRP |

| diameter | 2*0.8mm | |

| Inner sheath | material | LSZH |

| diameter | 1.8±0.2mm | |

| Color | Black | |

| Outer sheath | material | PE |

| diameter | ≥1.0mm | |

| Color | Black | |

| Aramid yarn | Kevlar yarn | |

| Inside Cable size (Height * width) | 2.0(±0.1) mm × 3.0(±0.2)mm | |

| Whole Cable sheath | 6.5±0.2mm | |

| Cable weight | 32KG±1KG | |

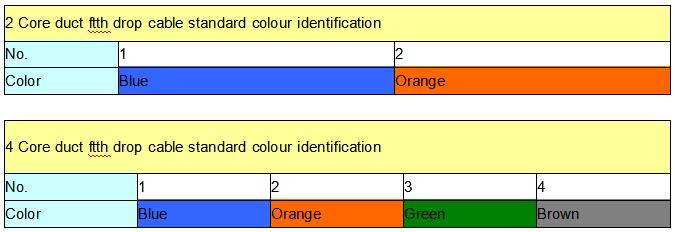

Standard Color of Fiber and Tube

The color of the individual fibers, shall be in accordance with the table as below:

Duct Drop Cable Mechanical Characteristic

| Items | Description | |

| Installation Temperature range | -20–+60℃ | |

| Operation and transport temperature | -40-+70℃ | |

| Min Bending Radius(mm) | Long term | 15D |

| short term | 30D | |

| Allowable Tensile Strength(N) | Long term | 500 |

| short term | 1000 | |

| Crush Load (N/100mm) | Long term | 500 |

| short term | 1000 | |

| Recommended Span (m) | 70 | |

| Installation sag | 1.5% | |

| Max. Wind Speed (m/s) | 25 | |

| Average Wind Speed (m/s) | 10 | |

Optical Characteristics

| Fiber style | Unit | SM

G652D |

SM

G657A1 |

SM

G657A2 |

||

| condition | nm | 1310/1550 | 1310/1550 | 1310/1550 | ||

| attenuation | dB/km | ≤0.36/0.23 | ≤3.5/0.21 | ≤3.5/0.21 | ||

| Dispersion | 1310nm | Ps/(nm*km) | ≤18 | ≤18 | ≤18 | |

| 1550nm | Ps/(nm*km) | ≤22 | ≤22 | ≤22 | ||

| Zero dispersion wavelength | nm | 1312±10 | 1312±10 | 1300-1324 | ||

| Zero dispersion slope | ps/(nm²×Km) | ≤0.091 | ≤0.090 | ≤0.092 | ||

| PMD Maximum Individual Fiber | [ps/√km] | ≤0.2 | ≤0.2 | ≤0.2 | ||

| PMD Design Link Value | ps/(nm²×Km) | ≤0.08 | ≤0.08 | ≤0.08 | ||

| Fiber cutoff wavelength λc | nm | ≧1180,≤1330 | ≧1180,≤1330 | ≧1180,≤1330 | ||

| Cable cutoff wavelength λcc | nm | ≤1260 | ….. | ….. | ||

| MFD | 1310nm | um | 9.2±0.4 | 9.0±0.4 | 9.8±0.4 | |

| 1550nm | um | 10.4±0.8 | 10.1±0.5 | 9.8±0.5 | ||

| Step(mean of bidirectional measurement) | dB | ≤0.05 | ≤0.05 | ≤0.05 | ||

| Irregularities over fiber length and point discontinuity | dB | ≤0.05 | ≤0.05 | ≤0.05 | ||

| Difference back scatter coefficient | dB/km | ≤0.03 | ≤0.03 | ≤0.03 | ||

| Attenuation uniformity | dB/km | ≤0.01 | ≤0.01 | ≤0.01 | ||

| Cladding diameter | um | 125.0±0.1 | 124.8±0.1 | 124.8±0.1 | ||

| Cladding non-circularity | % | ≤1.0 | ≤0.7 | ≤0.7 | ||

| Coating diameter | um | 242±7 | 242±7 | 242±7 | ||

| Coating/chaffinch concentrically error | um | ≤12.0 | ≤12.0 | ≤12.0 | ||

| Coating non circularity | % | ≤6.0 | ≤6.0 | ≤6.0 | ||

| Core/cladding concentricity error | um | ≤0.6 | ≤0.5 | ≤0.5 | ||

| Curl(radius) | um | ≥4 | ≥4 | ≥4 | ||

| Fiber style | Unit | SM

G652D |

SM

G657A1 |

SM

G657A2 |

||

| condition | nm | 1310/1550 | 1310/1550 | 1310/1550 | ||

| attenuation | dB/km | ≤0.36/0.23 | ≤3.5/0.21 | ≤3.5/0.21 | ||

| Dispersion | 1310nm | Ps/(nm*km) | ≤18 | ≤18 | ≤18 | |

| 1550nm | Ps/(nm*km) | ≤22 | ≤22 | ≤22 | ||

| Zero dispersion wavelength | nm | 1312±10 | 1312±10 | 1300-1324 | ||

| Zero dispersion slope | ps/(nm²×Km) | ≤0.091 | ≤0.090 | ≤0.092 | ||

| PMD Maximum Individual Fiber | [ps/√km] | ≤0.2 | ≤0.2 | ≤0.2 | ||

| PMD Design Link Value | ps/(nm²×Km) | ≤0.08 | ≤0.08 | ≤0.08 | ||

| Fiber cutoff wavelength λc | nm | ≧1180,≤1330 | ≧1180,≤1330 | ≧1180,≤1330 | ||

| Cable cutoff wavelength λcc | nm | ≤1260 | ….. | ….. | ||

| MFD | 1310nm | um | 9.2±0.4 | 9.0±0.4 | 9.8±0.4 | |

| 1550nm | um | 10.4±0.8 | 10.1±0.5 | 9.8±0.5 | ||

| Step(mean of bidirectional measurement) | dB | ≤0.05 | ≤0.05 | ≤0.05 | ||

| Irregularities over fiber length and point discontinuity | dB | ≤0.05 | ≤0.05 | ≤0.05 | ||

| Difference backscatter coefficient | dB/km | ≤0.03 | ≤0.03 | ≤0.03 | ||

| Attenuation uniformity | dB/km | ≤0.01 | ≤0.01 | ≤0.01 | ||

| Cladding diameter | um | 125.0±0.1 | 124.8±0.1 | 124.8±0.1 | ||

| Cladding non-circularity | % | ≤1.0 | ≤0.7 | ≤0.7 | ||

| Coating diameter | um | 242±7 | 242±7 | 242±7 | ||

| Coating/chaffinch concentrically error | um | ≤12.0 | ≤12.0 | ≤12.0 | ||

| Coating non circularity | % | ≤6.0 | ≤6.0 | ≤6.0 | ||

| Core/cladding concentricity error | um | ≤0.6 | ≤0.5 | ≤0.5 | ||

| Curl(radius) | um | ≥4 | ≥4 | ≥4 | ||