Description

Yingda preformed safety backup cable clamps can eliminate the disconnection, overheating, and other phenomena caused by the joint phenomenon of high-voltage transmission lines crossing important facilities (such as electrified railways and highways), ensuring that the wires can still be tightened to meet normal working tension, conduct current, reduce losses caused by power outages, and buy time for emergency repairs in case of accidents. When no accidents occur, the safety backup clamp can share some of the current and reduce the probability of accidents.

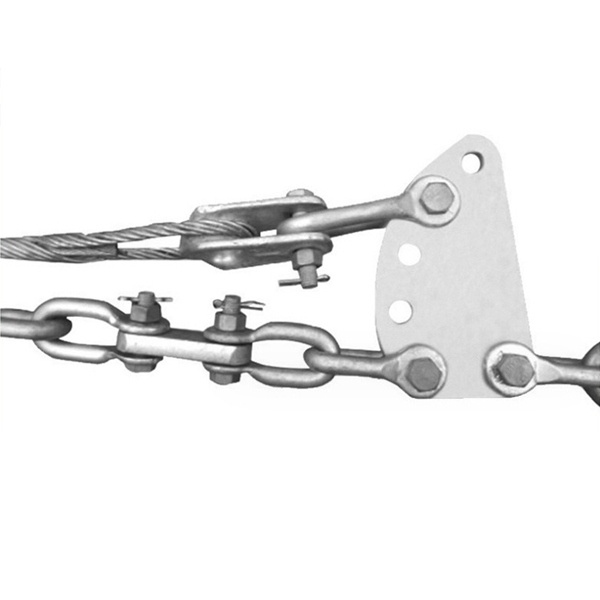

Suspension Clamp Bracket Structure

The pre twisted wire safety backup clamp consists of a set of load-bearing wire grip and an electrical shunt system.

- The components that carry the grip strength of the conductor include U-shaped hanging rings, TC embedded rings, pre twisted tension clamps, filling strips, and reinforced splicing strips, with a grip strength of not less than 80% of the maximum tensile strength of the conductor.

- The components for electrical shunt include: shunt bars, with a resistance not exceeding 1.1 times that of equal length wires.

Features of Suspension Clamp Bracket

- Relieve the stress concentration phenomenon of the compression tension clamp on the wire, while sharing the current transmission pressure of the compression tension clamp, avoiding the occurrence of overheating.

- Pre twisted safety backup cable clamp, with a gripping force of 40% of the wire breaking force, can hold the wire immediately in case of emergencies on the transmission line to prevent it from falling.

- The wire clamp evenly distributes the stress on the wire, does not damage the wire, improves the anti vibration ability of the wire, and greatly extends the service life of the wire.

- Good corrosion resistance, the material is completely consistent with the wire, ensuring strong corrosion resistance.

- Easy to install, the wire clamp can be quickly and manually installed on site, without the need for any special tools, and can be completed by one person.

The installation quality is easy to ensure, the installation consistency of the wire clamp is strong, no special training is allowed, and it can be inspected with the naked eye. The appearance is simple and beautiful

Order Information of Suspension Clamp Bracket

| Part no | Conductor | Part name | Material | Qty | Length (mm) | Weight (kg) |

| LSBN-07010 | LGJ-50/30 | Clevis | RTS≤70KN | 1 | 120 | 0.7 |

| LGJ-70/10 | Thimble shackle | TC-10 | 1 | 50 | 1.1 | |

| Preformed dead end | LSNL-22/G-1010 | 1 | 10 | 0.43 | ||

| Fill bar (steel strand) | GJ-6.0-940 | 1 | 10 | 0.17 | ||

| Strengthen connecting line | LSJBL-3100-2030 | 1 | 940 | 0.86 | ||

| Diversion strip | LSCS-1173 | 1 | 2030 | 0.57 | ||

| LSBN-09525 | LGJ-95/15 | Clevis | RTS≤70KN | 1 | 1370 | 0.7 |

| LGJ-95/20 | Thimble shackle | TC-10 | 1 | 120 | 1.1 | |

| LGJ-70/40 | Preformed dead end | LSNL-35/G-1060 | 1 | 50 | 0.53 | |

| LJ-120 | Fill bar (steel strand) | GJ-35-965 | 1 | 1060 | 0.3 | |

| Strengthen connecting line | LSJLB-3104-2120 | 1 | 965 | 0.98 | ||

| Diversion strip | LSCS-1440 | 1 | 2120 | 0.66 | ||

| LSBN-12025 | LGJ-120/25 | Clevis | RTS≤70KN | 1 | 120 | 0.7 |

| LGJ-120/20 | Thimble shackle | TC-12 | 1 | 50 | 0.12 | |

| LJ-150 | Preformed dead end | LSNL-50/G-1100 | 1 | 1100 | 0.68 | |

| Fill bar (steel strand) | GJ-50-1000 | 1 | 1000 | 0.43 | ||

| Strengthen connecting line | LSJLB-3107-2180 | 1 | 2180 | 1.22 | ||

| Diversion strip | LSCS-1630 | 1 | 1690 | 0.93 | ||

| LSBN-15025 | LGJ-150/20 | Clevis | RTS≤70KN | 1 | 120 | 0.7 |

| LGJ-150/25 | Thimble shackle | TC-12 | 1 | 50 | 1.12 | |

| LGJ-150/35 | Preformed dead end | LSNL-60/G-1180 | 1 | 1180 | 0.95 | |

| Fill bar (steel strand) | GJ-50-1000 | 1 | 1080 | 0.55 | ||

| Strengthen connecting line | LSNB-3109-2350 | 1 | 2350 | 1.64 | ||

| Diversion strip | LSCS-1630 | 1 | 1783 | 1.25 | ||

| LSBN-18530 | LGJ-185/25 | Clevis | RTS≤70KN | 1 | 120 | 0.7 |

| LGJ-185/30 | Thimble shackle | TC-12 | 1 | 50 | 1.12 | |

| Preformed dead end | LSNL-70/G-1300 | 1 | 1300 | 1.4 | ||

| Fill bar (steel strand) | GJ-70-1200 | 1 | 1200 | 0.78 | ||

| Strengthen connecting line | LSNB-3111-2670 | 1 | 2670 | 2.5 | ||

| Diversion strip | LSCS-1930 | 1 | 2100 | 1.87 |