Everyday we receive many inquiries about fiber optic cables from customers, but due to the wide variety of fiber optic cable models, different application scenarios and requirements, and significant differences in fiber optic cable structures, customers often do not have a clear understanding of what kind of fiber optic cable they need. Therefore, Yingda plans to use two articles to briefly analyze communication cables: commonly used communication cables and special communication cables. ‘Commonly used’ and ‘special’ are relative, and different operators and regions may have different understandings. This article focuses on explaining commonly used communication cables.

Commonly used communication cables are introduced in three parts: ordinary cables, FTTH drop cables, and ribbon cables.

1. Ordinary cable

Ordinary optical cables may be the earliest widely used optical cables in communication networks, including commonly used GYTA cables (commonly known as “pipeline cables”), GYTS cables (commonly known as “overhead cables”), GYTA53 cables (commonly known as “buried cables”), and GYTZA type optical cables (commonly known as “flame-retardant cables”).

Pipeline cable (GYTA)

GYTA cable has good waterproof performance and is suitable for occasions where pipeline laying is the main method, but it can also be laid overhead.

1.2 Overhead Cable (GYTS)

The core structure of GYTS cable is the same as that of GYTA, except that its sheath is double-sided chrome plated coated steel strip (PSP)+polyethylene. The structure of GYTS cable is shown in Figure 1.2.

Compared with GYTA cable, GYTS cable has better resistance to lateral pressure and is suitable for scenarios that require high lateral pressure, such as sections mainly laid overhead, or used for access to wide and passenger areas, as well as pipeline laying methods.

1.3 Directly buried cable (GYTA53)

GYTA53 cable can be understood as a double-sided chrome plated coated steel strip (PSP) armor on the outer sheath of GYTA cable, and finally extruded with a polyethylene outer protective layer to form the cable. The structure of GYTA53 cable is shown in Figure 2.3.

GYTA53 cable has good waterproof, anti lateral pressure, and anti tensile properties, making it suitable for direct burial laying. Due to the high cost and inability to expand capacity of directly buried cables, the new cable lines will no longer adopt the direct burial method. Directly buried cables are mainly used for maintenance of the original directly buried optical cable lines.

1.4 Flame retardant cable (GYTZA)

The structure of GYTZA cable is the same as that of GYTA; The difference is that the sheath of GYTA cable is made of polyethylene material, while the sheath of GYTZA cable is made of flame-retardant material.

GYTZA cable is mainly used for the incoming sections of core nodes and important aggregation nodes, and the length of each incoming cable section should generally not be less than 500 meters.

2 FTTH drop cable

FTTH Drop cable is mainly used for the introduction section of FTTH (from the fiber splitter box to the ONT equipment in the user’s home), which is divided into ordinary drop cable (GJXH), self-supporting drop cable (GJYXFCH), prefabricated drop cable, invisible drop cables, and prefabricated invisible drop cables.

2.1 Ordinary drop cable (GJXH)

GJXH cable is made by placing optical fibers in the center and two parallel steel wires or FRP on both sides as reinforcing elements, and extruding low smoke halogen-free flame-retardant sheaths to form the cable. The structure of GJXH cable is shown in Figure 3.1.

The commonly used fiber cores for GJXH cable is 1 or 2, and the short axis and long axis dimensions of the sheath are 2mm and 3mm respectively. The short-term allowable tensile force (minimum value) is 200N, and it is recommended to lay it along the wall or through the pipe, rather than hanging it in the air.

2.2 Self supporting drop cable (GJYXFCH)

GJYXFCH cable is a non-metallic ordinary drop cable (GJFXH) with an additional reinforcing element (steel wire or steel wire rope) attached to the outside. The structure of GJYXFCH cable is shown in Figure 2.2.

The commonly used fiber cores for GJYXFCH cable is 1 or 2, with a minimum allowable tensile force of 600N. It can be suspended for short distances (less than 50 meters) and is suitable for being introduced from outdoors to indoors.

2.3 Pre terminated Drop Cable

Pre fabricated drop cable is to add SC movable connectors at both ends of a fixed length 1-core GJXH or GJYXFCH cable to reduce the workload of on-site termination during installation. Pre formed drop cable is introduced as shown in Figure 2.3.

2.4 Invisible fiber optic Cable (GJIXH)

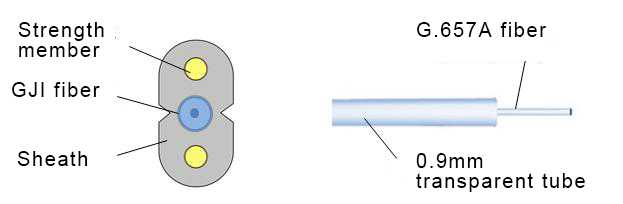

The structure of GJIXH cable is basically the same as that of ordinary drop cable, except that the middle part of GJIXH optical cable is a single core invisible cable (GJI). GJI cable is essentially a tight buffer, which is wrapped with a transparent sheath with a diameter of 0.9mm around an uncolored G.657 fiber optic cable. The structure of GJIXH cable and GJI cable is shown in Figure 2.4.

GJI cable has a thin outer diameter and is fully transparent; When laying, fix the cable with glue along with the wall base lines and door and window decorative strips around the building, and the wiring is concealed and aesthetically pleasing. When introducing GJIXH fiber optic cables, the indoor part can be torn open and the reinforcing components and sheath of the cable can be cut off, leaving only GJI cables for laying.

The installation of GJI cables is difficult and costly, making them suitable for scenarios where users have high requirements for the aesthetics and concealment of indoor wiring.

2.5 Pre terminated invisible cable

Pre terminated invisible optical cable is to add SC connector at both ends of a fixed length GJI cable to reduce the workload of on-site end installation. The pre terminated invisible optical cable is shown in Figure 2.5.

When using a prefabricated invisible fiber optic cable, one prefabricated fiber optic cable is cut from the middle and divided into two pigtails according to its length, which can be used for indoor laying for two users respectively; The outdoor part of the user uses drop cables; The drop cable for outdoor use and the invisible fiber optic cable for indoor use are fused together at suitable locations at the entrance.

3 Ribbon Cables

Ribbon fiber is a thin flat ribbon formed by parallel arrangement of 4-24 optical fibers and UV curing. The optical cable that uses ribbon fiber inside the cable is called Ribbon cable.

3.1 Layer Twisted Ribbon Cable (GYDTA)

GYDTA cable has the same structure as GYTA, but the difference is that each loose tube contains multiple 4-core, 6-core, or 12 core ribbons fiber instead of loose fibers. The structure of GYDTA cable is shown in Figure 3.1.

GYDTA cable is suitable for laying in pipelines or overhead ways. The model and specification of the fiber optic cable with 12 cores and 288 cores inside the cable are GYDTA-288B1.3-12F.

3.2 Skeleton Ribbon Cable (GYDGA)

The structure of GYDGA cable is shown in Figure 3.2. The ribbon fiber is placed in a skeleton groove made of high-density polyethylene (HDPE), with a single steel wire or multiple stranded steel wires at the center of the skeleton. Wrap a layer of waterproof tape around the skeleton, longitudinally wrap it with double-sided plastic coated aluminum tape (APL), and extrude a polyethylene (PE) sheath. Place a tear rope between the aluminum strip and the waterproof strip to facilitate the stripping of the sheath.

GYDGA cable is suitable for laying in pipelines or overhead, and the ribbon fiber inside the cable is generally 4-core or 6-core. GYDGA cable has high rigidity, and although the curvature radius requirement is the same as that of ordinary cables, it may be more difficult to operate. The model and specification of 6-core fiber optic tape and 288 core optical cable are GYDGA-288B1.3-6F.