Description

Yingda Pushable patch cords are pre terminated and polished SC and LC connectors with a wall protective sleeve or case, after being pushed or pulled through a wall hole or microduct, the smooth wall protective sleeve is easily removed and an outer housing is snapped into place. The whole process dont need a fusion splicer or other fiber optic tools, easy to operate.

Pushable Patch Cord Features

- All patch cords meet GR-20, GR-326 and GR-1435 standards

- Available in SC/UPC, SC/APC connectors with 3mm boot

- Metal wall protection sleeve is easily removed and outer housing is snapped into place.

- Tool-less installation , tech friendly, decrease deployment time and reduce the installation cost

- Best choice for microduct, wall through, pipeline fiber optic cabling

Pushable Patch Cord Technical Specifications

| Connector type | SC LC |

| Fiber count | 1 core |

| Polish method | UPC, APC, PC |

| Protective sleeve material | Zinc alloy, copper |

| Insertion loss | ≤0.3dB |

| Return loss | UPC≥50dB, APC≥60dB, PC≥30dB |

| Ferrule material | Ceramic |

| Working temperature | -40~+85℃ |

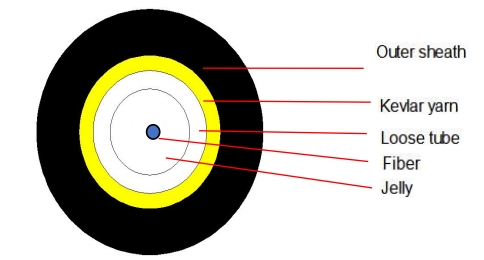

Air Blown Fiber Optic Cable Strucutre and Specification

| Item | Description | |

| Number of fiber | 1 core | |

| Fiber type | Corning G.657A2 | |

| Loose tube | Diameter | 2.8±0.2 |

| Color | Black | |

| Material | PBT | |

| Cable weight | 7.2kg/km | |

| Crush load (N/100mm) | Long term | 100 |

| Short term | 500 | |

| Installation temperature (℃) | -5 ~+50 | |

| Storage temperature (℃) | -10 ~+70 | |

| Operation and transport temperature (℃) | -10 ~+70 | |